Discover the Artistry of In-Mold Decorations in Production

Discover the Artistry of In-Mold Decorations in Production

Blog Article

Mastering In-Mold Decorations: Approaches, Fads, and Finest Practices for Optimum Results

In the world of manufacturing, the art of in-mold decors stands as a critical aspect of item style and manufacturing. As markets consistently look for ingenious methods to enhance aesthetic appeal and performance, mastering the intricacies of in-mold decors has become a vital ability. From picking the best products to incorporating sophisticated design patterns, the journey in the direction of achieving optimal outcomes in this domain name is multifaceted. By delving right into the methods, fads, and best practices that underpin successful in-mold decor procedures, services can unlock a realm of possibilities that not only boost the visual allure of their products however additionally streamline manufacturing efficiency and reinforce customer involvement.

Material Selection

Material choice is a critical aspect of mastering in-mold decors, as it straight affects the quality and sturdiness of the end product. When choosing products for in-mold decors, it is important to consider elements such as compatibility with the molding procedure, the desired aesthetic end result, and the ecological problems the product will encounter. Polycarbonate products like polycarbonate, ABDOMINAL, and polypropylene are typically made use of for in-mold decors because of their adaptability and capacity to attain detailed designs. These products use superb moldability, allowing manufacturers to develop complicated forms and patterns with precision.

Moreover, the chosen product should have good attachment buildings to guarantee that the decor adheres firmly to the substratum during the molding procedure. Adhesion between the decoration and the material is critical for avoiding delamination and making certain lasting aesthetic appeal. In addition, materials with high warm resistance are preferred for in-mold designs, specifically for items that will certainly be revealed to elevated temperatures during their lifecycle. By very carefully picking the appropriate material for in-mold decorations, suppliers can enhance the overall quality and longevity of their items, meeting the assumptions of both end-users and clients.

Style Advancement

An essential consider advancing the area of in-mold designs is the constant exploration and implementation of layout development techniques. Layout technology plays a critical duty in improving the aesthetic appeal, functionality, and total top quality of products manufactured making use of in-mold design processes. By incorporating cutting-edge style aspects, manufacturers can separate their items on the market, attract consumers, and stay in advance of competitors.

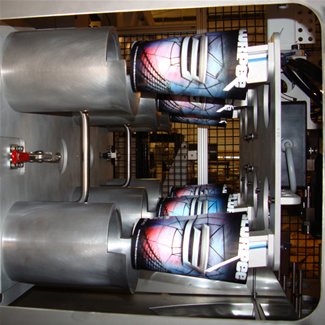

Among the crucial facets of style technology in in-mold designs is the integration of detailed patterns, structures, and graphics that were formerly challenging to attain with standard decoration approaches. Advanced technologies such as 3D printing and electronic design tools allow designers to produce complex and in-depth designs that can be effortlessly transferred onto shaped components. Additionally, using dynamic shades, metallic surfaces, and special results like gloss or matte structures can better elevate the aesthetic appeal of in-mold embellished products.

Additionally, layout development expands beyond appearances to include useful enhancements such as ergonomic shapes, incorporated attributes, and customizable aspects that accommodate certain customer needs. By accepting layout innovation, producers can unlock new opportunities for personalization, imagination, and item differentiation in the affordable landscape of in-mold designs.

Production Effectiveness

Effective production procedures are crucial for converting the cutting-edge styles developed in the area of in-mold decors into top quality finished products that meet market needs and consumer expectations. In the world of in-mold designs, manufacturing effectiveness encompasses numerous crucial aspects that add to the general success of the manufacturing procedure.

Automation not only speeds up the manufacturing process yet additionally enhances precision and repeatability, leading to a more uniform and high-grade end product. In general, an this hyperlink alternative technique to production performance is paramount in taking full advantage of the capacity of in-mold design methods and accomplishing ideal results in the competitive market landscape.

Quality Assurance Steps

What are the crucial methods for making sure rigid high quality control procedures in the world of in-mold designs? Quality control actions are paramount in in-mold decor procedures to make sure the production of high-grade and perfect completed products. One vital approach is the execution of extensive evaluation protocols at every phase of the production process. This entails carrying out extensive visual examinations, dimensional checks, and shade consistency analyses to determine any incongruities or defects at an early stage.

Using innovative innovations such as computerized evaluation systems can likewise enhance the high quality control procedure by supplying exact and reputable information for evaluation. These systems can discover flaws that may be missed by hands-on inspections, thus enhancing overall item top quality and consistency.

Regular training and advancement programs for staff members involved in the in-mold decoration process can likewise contribute to maintaining high-grade criteria. By informing team on finest methods, top quality expectations, and the significance of interest to information, firms can cultivate a society of quality awareness throughout the company.

Customer Allure

To enhance the marketability of in-mold decoration products, catering and comprehending to customer preferences play a crucial duty in establishing their appeal and success. Customer appeal in in-mold designs is influenced by various elements, including design looks, shade options, toughness, and total capability. Customers are progressively looking for individualized and distinct products that reflect their individuality and style. Therefore, offering modification alternatives such as individualized layouts, shade variations, and textural elements can significantly boost the allure of in-mold design products.

Final Thought

In-mold designs use a efficient and functional method to improve item appearances. Understanding in-mold designs requires a holistic strategy that thinks about all aspects of the manufacturing process to make certain success.

In the world of manufacturing, the art of in-mold decors stands as a crucial element of product layout and production. Layout advancement plays an important duty in boosting directory the aesthetic Going Here charm, capability, and general high quality of items made utilizing in-mold decor procedures.One of the vital facets of style innovation in in-mold decors is the integration of detailed patterns, structures, and graphics that were previously testing to attain with conventional decor methods.Reliable production procedures are important for translating the cutting-edge designs established in the area of in-mold designs right into premium ended up products that fulfill market demands and customer assumptions. Providing modification options such as individualized designs, color variants, and textural elements can substantially boost the appeal of in-mold decoration items.

Report this page